+86-+86-13861820877

Tel:

Tel:+86-510-88602712

Fax:

Tel:+86-510-88602712

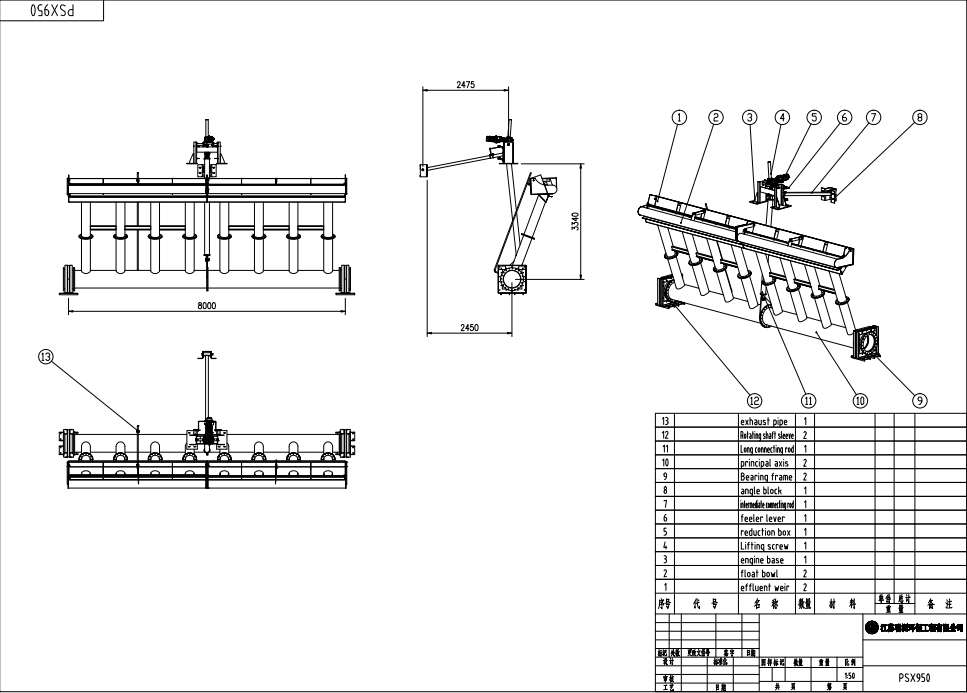

Technical requirements of MW-PSX-950:

| No. | Item | Parameter/model |

| 1 | Maximum decanting capacity | 945m3/H |

| 2 | Minimum decanting capacity | 744m3/h |

| 3 | Decanting depth | 1.24m |

| 4 | Water discharge method | Both end outlet |

| 5 | Body material | SS316L |

| 6 | Submerged bearing | PE |

| 7 | Power | 0.75Kw |

| 8 | Brand of speed reducer | SEW |

| 9 | Brand of electrical control cabinet | Not included (to be purchased by the Buyer) |

Product Description:

Decanter, also known as skimmer, was the most important equipment in SBR(CASS) technology.

Because all kinds of sequential batch activated sludge methods adopt periodic drainage, the water level in the pool changes during drainage. In order to ensure that the water level in the pool will not be disturbed during drainage, the supernatant will always be located at the top, which requires the use of a water outlet system that can be adjusted with the change of water level, namely the skimmer.

Rotary skimmer is a high-tech product developed by our company on the basis of digesting foreign technologies. This equipment is specially designed for sequencing batch biological processing system, with excellent hydraulic mechanical performance. Its unique hinged four-link drive mechanism ensures the laminar flow of water entering the outlet system during the skimming process, and the skimming speed is stable and adjustable.

Unique four-link drive mechanism can ensure drainage effect. Unique and stable underwater support to eliminate major hazards. The unique slag-liquid sorting device can completely prevent the scum from entering the effluent system. Unique structure, can achieve flexible water way. Minimal energy consumption and high efficiency.

Benefits:

• Free movement in vertical direction, maximum distance from sludge layer during sedimentation and decanting.

• Floating sludge does not influence effluent quality.

• Low velocity of flow resulting in low risk for occurrence of whirls and sludge waste.

• Prevention of sludge penetration into outflow pipe.

• A minimum of maintenance work and no electrical equipment.

•Strong adaptability, through internal parameters set and adjust the frequency converter, can change the running speed of the water and the corresponding movement range, adapt to different water requirements

•Sealed rotary joint, flexible rotation, good sealing, no drainage can replace the sealing ring

•Underwater parts are all made of stainless steel, do not need maintenance, drive and control equipment maintenance is convenient

•The whole water decanter with strong support, can work under various pressure encountered

•Water decanter adopt fission structure, easy to transport and install

•Elaborate structure, beautiful appearance, save installation space

Manufacturing requirements of the equipment:

Material: Body material being SS316L.

Surface treatment: acid pickling in welding line with stainless steel

Design standards: CTJ/176-2007

The package and transportation requirements of the equipment.

The equipment body: non-packed

Elevating screw and Speed reducer: wooden package, conforming to the export and shipping regulations.