Product Description:

● The MW-DY series of belt filter press dewatering machine is a new type of dewatering machine produced on the basis of learning, importing, digesting imported dewatering machine. It is widely used in the sludge (material) dehydration of coal, chemical industry, metallurgy, building materials, food, paper, municipal water supply and drainage industry and so on. It is an ideal equipment for material recovery and environmental governance.

● The MW-DY series of belt filter press dewatering machine is a new type of dewatering machine produced on the basis of learning, importing, digesting imported dewatering machine. It is widely used in the sludge (material) dehydration of coal, chemical industry, metallurgy, building materials, food, paper, municipal water supply and drainage industry and so on. It is an ideal equipment for material recovery and environmental governance.

● It is equipped with advanced sludge pre-treatment equipment, whichhas a good sludge flocculation effect and reduces the operating cost; it is equipped with sludge distribution mechanism and sludge distribution roll, which enables the even distribution of sludge and even thickness of sludge cake to extend the service life of the filter belt; equipped with water-saving high pressure cleaning nozzle and the nozzle washing mechanism, the filter belt could have good reproducibility, dehydrate stably, and nozzle could be washed timely; washing pipes are equipped with filter, which could take advantages of effluent water of secondary sedimentation tank to wash filter belt, saving flushing water cost (according to user’s requirement); drive mechanism selects the imported inverter, which enables the stepless speed range of belt to be up to 1:10. It could adapt to various types of sludge dewatering, increasing sludge dewatering rate; the gravity dewatering zone is equipped with sludge rake which can be lifted. The long time of gravity dehydration destroys the surface tension of sludge and improves the gravity dehydration effect; overall layout of the frame is open type,making it easy to observe the operation of equipment and cleaning of the filter cloth on the roll; reasonable pneumatic path design and high-quality pneumatic components, ensures the stable operation of equipment, improves equipment service life and reduces maintenance cost.

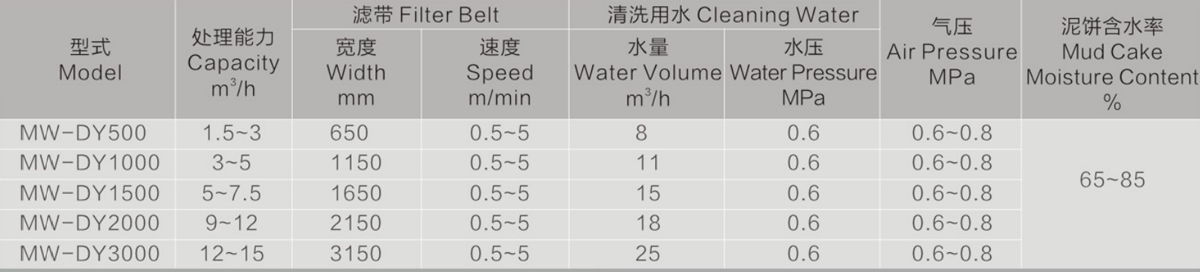

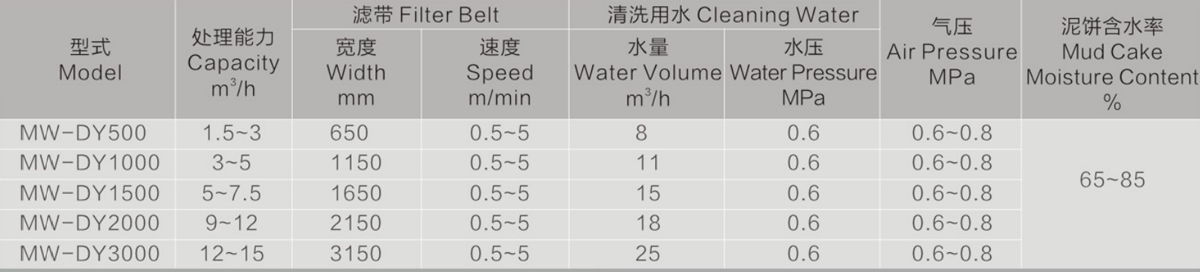

Main technical parameters: